India’s manufacturing sector, which saw a booster shot when the government announced sweeping GST rate cuts, now faces an operational crisis with China’s latest rare earth export curbs.China’s export restrictions, now including light rare earth magnet components, are expected to deepen the difficulties faced by Indian firms in the automotive, consumer electronics and industrial machinery sectors. These companies were beginning to recover following GST reductions when Beijing implemented these new measures, according to an ET report.

How Will China’s Rare Earth Curbs Hit Indian Manufacturing ?

China’s Ministry of Commerce has issued new regulations stipulating that components containing rare earth magnets more than 0.1% of the total cost will require export clearance from regional authorities starting November 8.Industry leaders who spoke to ET indicated that the restrictions will impact the import of components, sub-assemblies and specific light rare earth magnets. Indian manufacturers had been using these as temporary solutions to manage the existing limitations on heavy rare earth magnet exports from their northern neighbour.

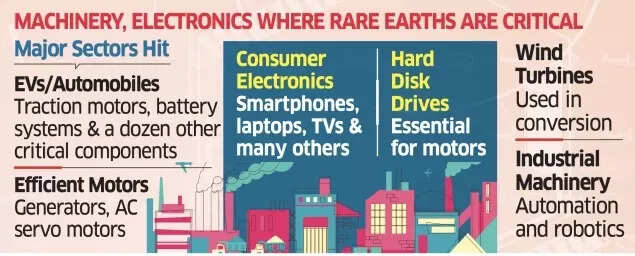

Rare earths critical

Electric vehicle motors, vehicle speed detection systems and automatic gear shifting mechanisms require rare earth magnets in approximately twelve essential components for their operation.“The scope of the restrictions which has now been announced is so vast and so consequential that it will impact every sector, be it aerospace, defence, automobiles, consumer electronics or industrial machinery,” said a senior industry executive quoted in the report.“It will hit all manufacturers who were or have started importing traction motors, rotary assemblies, electronic parts and components for battery systems from China after the stoppage in supplies of heavy rare earth magnets to India,” the executive added.Another industry executive told the financial daily that each company will be impacted. While the executive acknowledged that China’s latest notification gives time to make arrangements, the impact could still be felt.“…Even if I develop alternate sources, it does not necessarily imply I will not be impacted. The restrictions are wide-ranging, covering everything from raw materials to equipment to technologies and components,” the executive noted.In automotive manufacturing, production depends heavily on countless components, and disruption at any supplier within the supply chain poses a significant challenge, the executive explained. The absence of even a single component can halt the entire manufacturing process, rendering all other available parts unusable, he added.